Example of IBED-Coated Titanium Alloy Component

When orthopedic implants such as knees, hips, and shoulders, are implanted in the body and used as articulating elements they are subjected to wear and corrosion. The wear debris will be released into the body, transported to and absorbed by bone, blood, the lymphatic tissue, and other organ systems. The wear debris has been shown to produce long-term bone loss and loosening of the implant, and, even very low concentrations of metallic wear debris are suspect in causing adverse toxic, inflammatory, and immunologic tissue reactions. Implants made from metal alloys such as Co-Cr-Mo and Ti-6Al-4V are susceptible to wear and metal debris release. Ti-6Al-4V alloy has particularly poor resistance to abrasive wear and the Food and Drug Administration (FDA) requires that this titanium alloy be treated to improve wear-resistance if it is to be used for orthopedic implants.

Beamalloy Technologies has developed an advanced IBED Titanium Nitride coating within our proprietary TIONEX® family of wear resistant coatings, which is designed specifically for orthopedic implants. The IBED process is ideal for these products since it proceeds at a temperature below 300 F and poses no risk of bulk property distortion or dimensional changes to coated components. Termed TiN-Plus, the coating has been approved by the FDA for use on knee femorals made from Ti-6Al-4V.

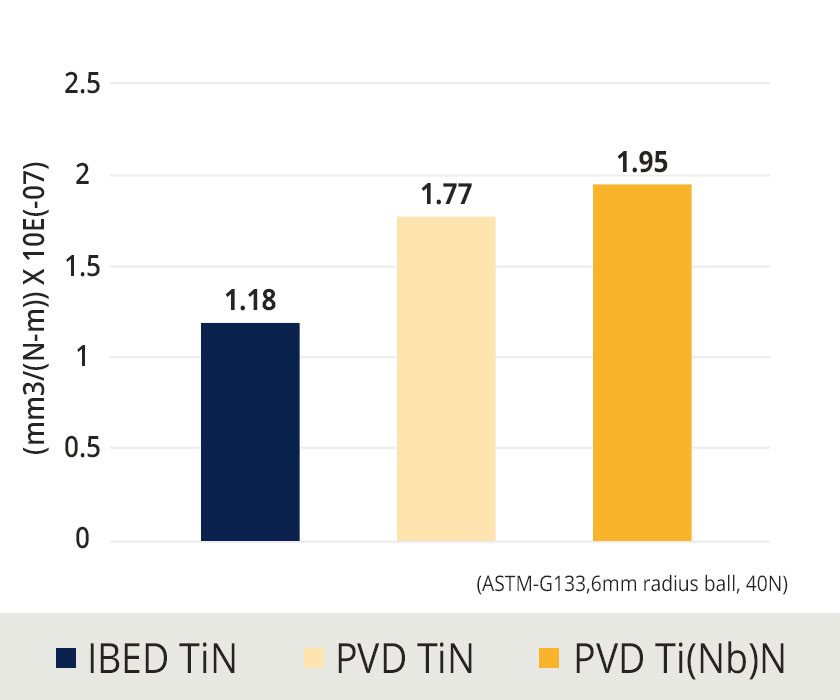

Key materials properties of the IBED TiN-Plus coating were measured and compared to conventional PVD TiN coatings also deposited on Ti-6Al-4V substrates. The properties measured include Scratch/Adhesion (ASTM C1624), and Pin-On-Disk wear (ASTM G133).

Production Ti-6AI-4V Knee Femoral

IBED TiN-Plus Coated

5 Microns Thick

Finish:0.02 microns (RA)

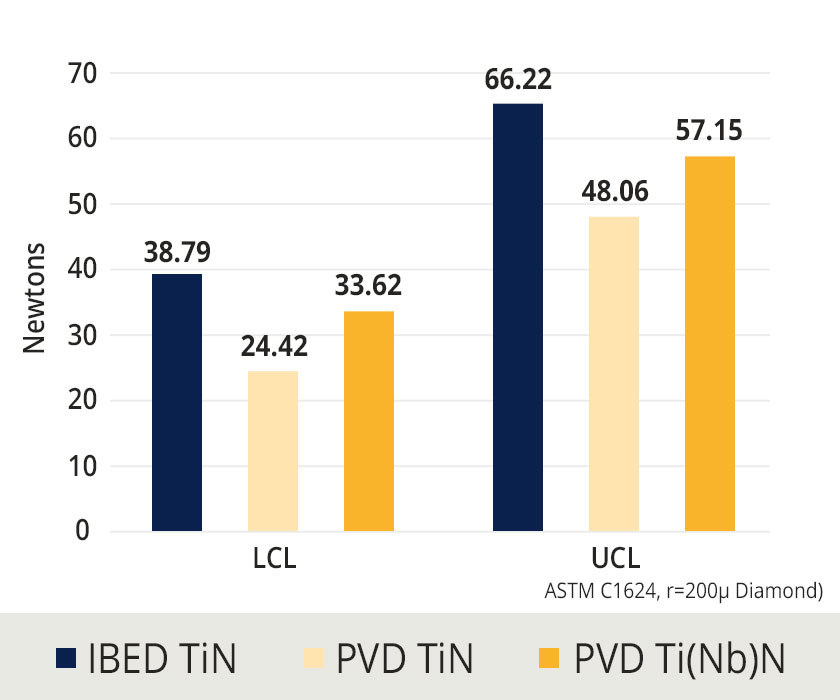

Scratch/Adhesion: IBED VS PVD Coatings

Cohesion within the volume of a coating under loading conditions will be determined by the trade-off between hardness and modulus (stiffness). Progressive linear scratch testing of IBED TiN-Plus coatings illustrates improved coating cohesion (LCL) due to an optimum trade-off between hardness and modulus. Likewise, coating spalling in IBED TiN-Plus coatings is reduced as illustrated by the higher UCL.

Improvement of the performance of coated components in the face of abrasive and fatigue wear is dependent on the properties of the coating-substrate couple. Optimum performance is obtained when the properties of the coating and substrate are matched properly. The IBED process allows tailoring of the hardness and modulus properties of the TiN-Plus coating which leads to better overall wear performance when compared to TiN coatings deposited by conventional PVD processes.

POD Wear Rate: IBED VS PVD Coatings

Tablet Punches & Dies

Capsule Tamping Pins

Capsule Dosing Disks

Dosators

Coating Spray Nozzles

Tablet Press Components

Blister Packaging Plates

Example of IBED-Coated Steel Tooling

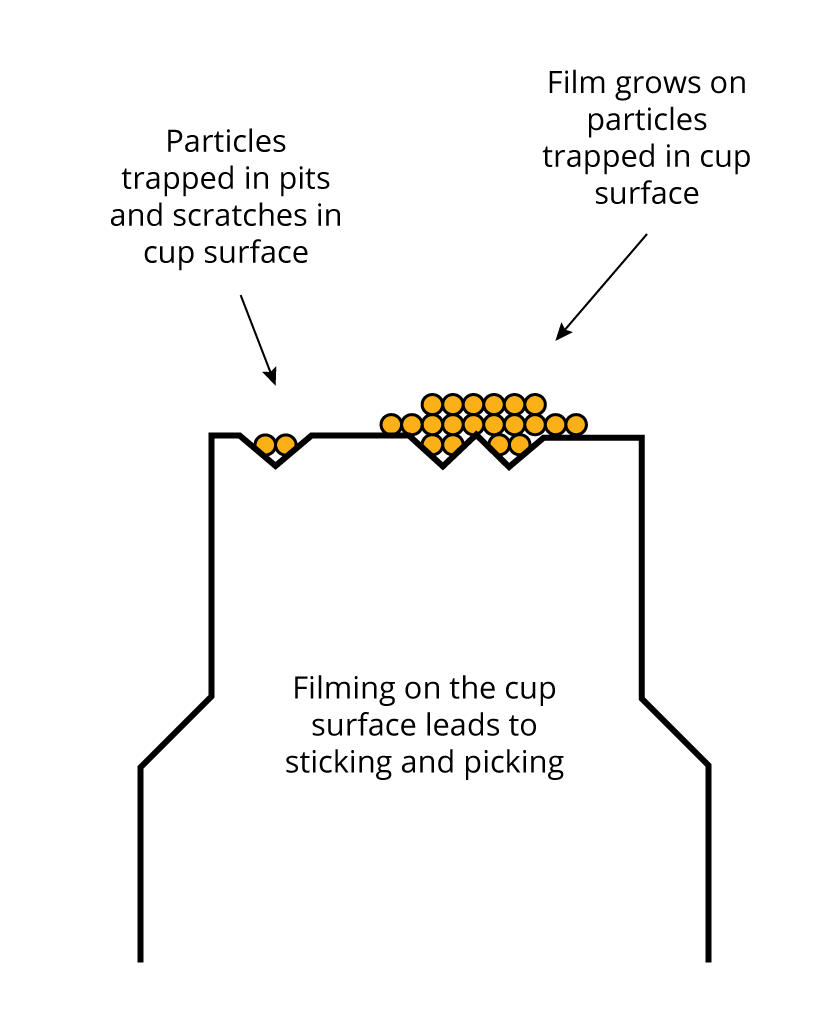

A major challenge to manufacturers of solid dose tablets in the pharmaceutical, nutraceutical, food supplement, candy, and chemical industries is compression tooling performance. When feed stock powders are compressed, the working surfaces of the tooling can develop filming and sticking which requires that tablet press operation stop and the tooling removed for cleaning/polishing. One of the major causes of this filming and sticking is degradation of the surface finish on the tooling, and even though compression tooling is made from hardened steels, their working surfaces are still prone to both wear and corrosion. Small micron-sized scratches and pits will trap powders in the tooling surface and start to build up eventually causing filming, sticking, and picking resulting in costly interruptions of tablet production.

Beamalloy developed a series of specialized IBED Titanium Nitride and Chromium Nitride coatings for the family of steels used for compression tooling, all designed to help reduce the filming, sticking, and picking. The IBED coatings provide enhanced wear- and corrosion-resistance to the working tips of the punches. The coatings preserve the finish on the punch cup surfaces which reduces the trapping of powders in the cup surface.. The key to success is using coatings deposited by the IBED process since they do not degrade the original surface finish on the punch tips, they do not soften the tool bulk material or change the dimensional tolerance of the tooling.

Beamalloy Technologies, LLC has over 25 years of experience coating tablet compression tooling for the pharmaceutical, nutraceutical/food supplement, candy, and chemical industries. We work directly with manufacturers of tableted unit dose materials and in addition we work closely with all the major US tablet tooling manufacturers. Including Natoli Engineering, Elizabeth Carbide Die (Pennsylvania and North Carolina), and Wilson Tool who all recommended us.