A major cause of sticking on production tableting punches is the mechanical interlocking of powders on punch cup surfaces. Roughened surfaces act to trap powders during compression. As the sequential tablet is compressed the cup faces begin to film, the sticking eventually necessitates that production is stopped to clean or polish the punches.

Coatings can help reducing wear and corrosion on the cup faces of tableting punches, delaying or eliminating the onset of surface smoothness of coatings can also have a significant impact on the initial performance of coated tools and components. It is, therefore, critical that you select a coating and coating process that does not degrade the original finish of your cup face surface.

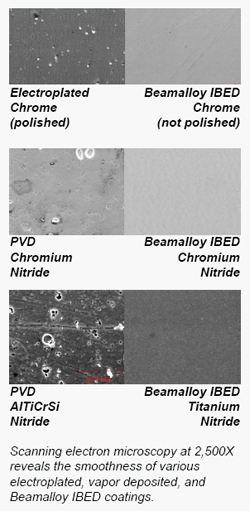

Conventional coating processes such as electroplating and physical vapor deposition (PVD) inherently generate coatings with microscopic-level rough surfaces. Cracks, pits, and voids are necessarily part of the processes, not the materials. While small, these micron-sized surface defects can trap powders and lead to tablet sticking.

Beamalloy IBED (Ion Beam Enhanced Deposition) coatings precisely replicate your original surface finish and provide conventional coating methods.

Beamalloy IBED coated surfaces are as smooth as your original punch face and contain no such defects enabling you to virtually eliminate mechanical entrapment as a source of your sticking problems, and improve your productivity.