Beamalloy Technologies, LLC is a pioneer in developing an advanced wear resistant PVD coating technology termed Ion Beam Enhanced Deposition (IBED). We have over twenty years of experience in successfully applying our advanced IBED coatings to a variety of precision engineered components and tools for customers in a variety of industrial, aerospace, and medical markets. Our patented IBED processes can produce hard nitride coatings such as titanium nitride (TIONEX®) and chromium nitride at temperatures below 350˚F. Thus finished parts fabricated from temperature-sensitive materials such as hardened steel and high-performance titanium alloys can be coated without the risk of degrading their bulk mechanical properties or critical dimensionality. We provide toll coating services and surface-engineering expertise to our customers from our facility in Plain City, Ohio. Our Quality System is ISO 9001/2015 and ISO 13485/2016 certified.

IBED Process Features

Low Temperature (<350˚F)

Properties superior to conventional PVD

Metallurgical bonding into the substrate

Pin-hole-free coatings

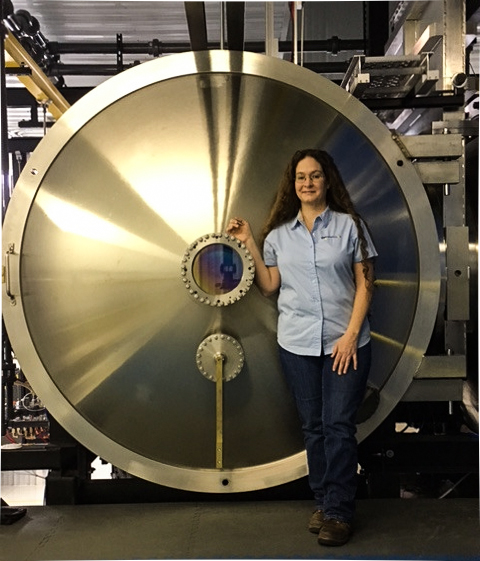

New 6-foot diameter coating system

Highly uniform coating of the 3D parts

Current Market Applications

Titanium and titanium alloy components

Hardened steel components

Plastic, ceramic, and glass substrates

Production tooling

Precision mechanical components

Orthopedic/dental implants

An improved alternative to hard chrome plating

An improved alternative to conventional PVD

Customer Service

Quick-turnaround IBED toll coating

Custom coating development

Materials/mechanical analysis

Established relationships with specialized analytical laboratories

Process/product validation

Custom equipment design/build

Click below to learn more about the IBED process, our services, and current market applications.