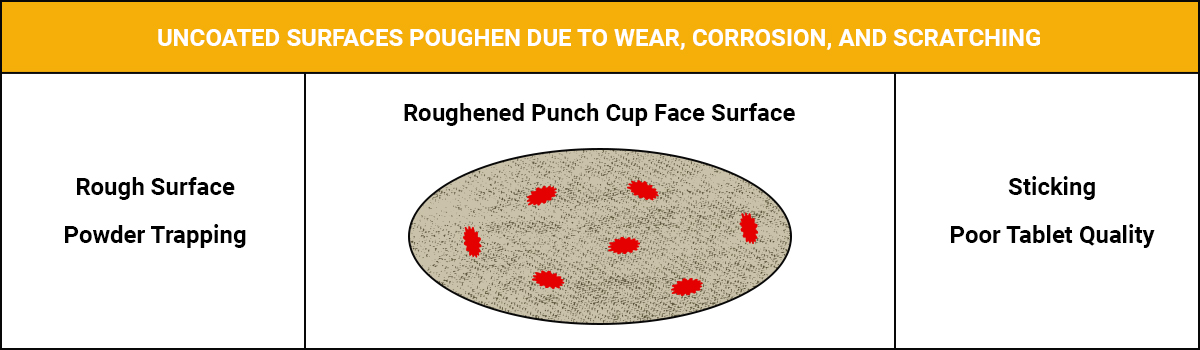

A major cause of sticking on production tableting punches is mechanical interlocking of powders on punch cup surfaces. As the cup faces of tableting punches wear and corrode, the roughened surfaces act to trap powders during compression. As sequential tablets are compressed the cup faces begin to film, and eventually sticking begins which necessitates that production be stopped to clean and polish the punches.

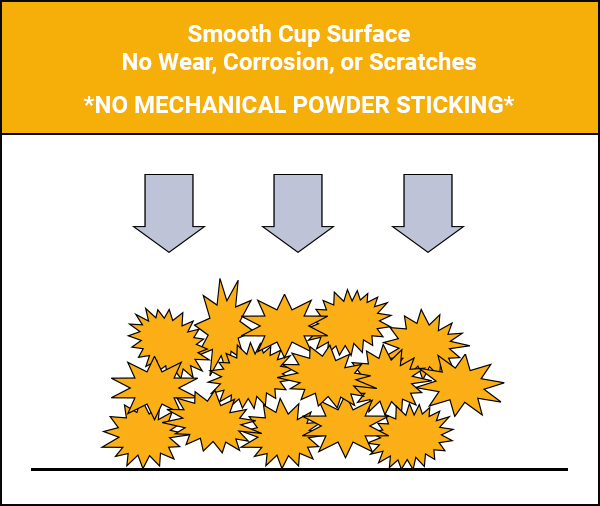

By coating the cup faces of punches with wear- and corrosion-resistant coatings using the precision Ion Beam Enhanced Deposition (IBED) process the smoothness and mechanical integrity of the surface is preserved thereby stopping mechanical sticking. The IBED process does not distort the dimensions of the punch and does not degrade the original polished finish on the cups of new punches.