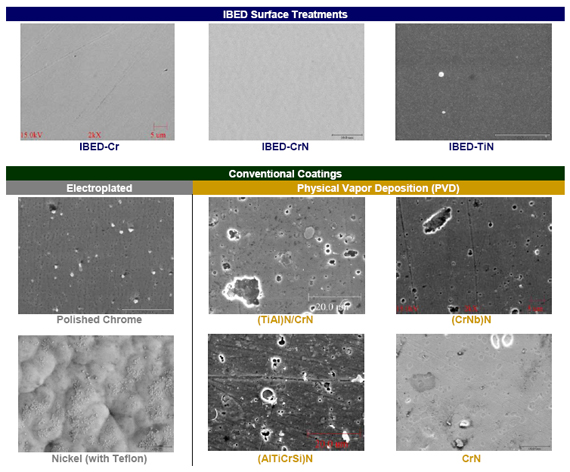

Coatings used to reduce wear and corrosion on the surfaces of pharmaceutical tooling must be chosen such that they do not degrade the original finish of the tool surface. Conventional coating processes such as electroplating and physical vapor deposition (PVD) generate coatings with microscopic-level rough surfaces. The surfaces of coatings deposited using the ion beam enhanced deposition (IBED) process are extremely smooth on a microscopic level.

Scanning electron microscopy (magnification of 2,000X) shows the micron-sized surface defects present on plated and PVD coatings that can trap powders and lead to tablet sticking. There are no micron-sized surface defects which will trap powder granules thus leading to sticking on IBED protective coatings. From punches and dies to dosators and tamping pins, Beamalloy is helping the pharmaceutical industry manage sticking, picking, corrosion, and wear every day. IBED surface treatments can optimize the microscopic physical and chemical surface properties of your tooling, significantly enhancing your performance and productivity.