From punches and dies to dosators and tamping pins, Beamalloy is helping the pharmaceutical industry manage sticking, picking, corrosion, and wear every day. Among the variables critical to performance are the microscopic physical and chemical surface properties of the tooling. IBED surface treatments can optimize these properties and significantly enhance your tooling performance.

Learning from Experience

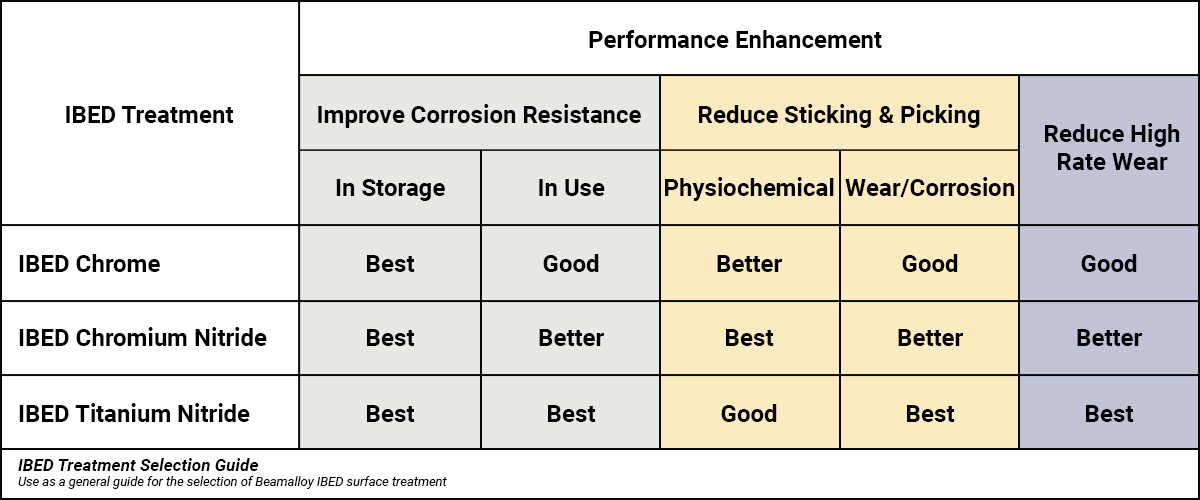

Side-by-side testing is the best way to determine the optimal IBED surface treatment and finish for every unique situation. In cases where such trials are not practical or are not an option, use of this guide will significantly increase the probability of initial success when choosing an IBED surface treatment.

Nanofinishing

The measurable difference in smoothness between standard IBED treatment and treatment with Nanofinishing is slight by traditional standards. This difference is measured in nanometers, but has proven to be of significant importance in many situations. It is not necessary in all cases, but we strongly recommend considering Nanofinish for use with active compounds or excipients that exhibit a particularly high degree of natural sticking.

You’re Not Alone

At Beamalloy, we are committed to providing the best available surface treatments, technical support, and service in the industry. For further consultation when conditions do not meet the parameters of this guide, or when specific knowledge of a situation suggests a performance result not predicted in this guide, please contact us.

We have the technical experience and capabilities necessary to help you manage your pharmaceutical manufacturing challenges … from the most straightforward to the most challenging. We look forward to helping you enhance your product quality, improve your productivity, and reduce your total cost of operation.