Beamalloy Technologies, LLC today announced completion and installation of a large industrial-scale coating system based on its’ patented ion beam enhanced deposition (IBED) technology. The new coating system allows deposition of hard coatings such as Titanium Nitride directly on the surfaces of components made from materials including most metals, ceramics, and glass.

Dr. Arnold Deutchman, Chairman and Director of R&D stated that the coating system is designed for production-scale processing of single large components or batches of smaller components. Titanium Nitride coatings up to 5 microns thick can be deposited on complex 3D parts with ultra-high precision in thickness and uniformity. The materials and mechanical properties of the IBED Titanium Nitride coatings exceed those of conventional PVD-deposited Titanium Nitride coatings. And the IBED technology allows processing temperature to stay below 300 degrees Fahrenheit.

Dr. Deutchman further commented that, “our current customers have been very happy with the performance of our IBED Titanium Nitride coatings and the high degree of precision and repeatability in coating properties that we can provide Applications include components used in aircraft/aerospace systems, medical devices, chemical processing equipment, oil and gas drilling and logging equipment, industrial equipment, and manufacturing tools and dies.

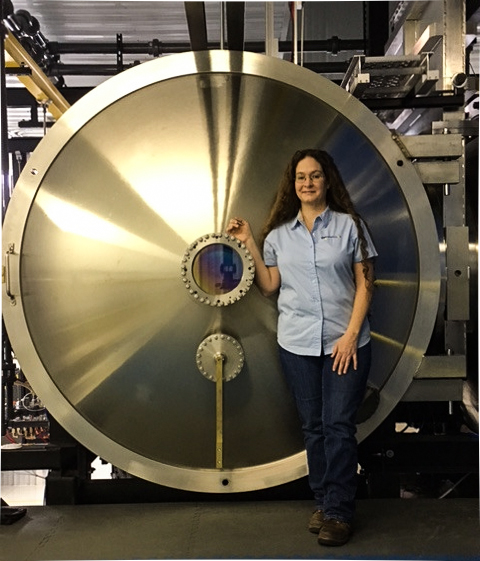

Beamalloy Technologies operates the new large scale system exclusively at its’ ISO 9001:2015 & 13485:2016 certified service center in Plain City, Ohio. The service center operates the largest IBED coating system in the United States, and is staffed and equipped for quick turnaround processing.